Delivery capability

Increasing efficiency through value stream orientation

By optimizing value streams, you reduce unnecessary processes and improve the flow of added value. The aim is to identify bottlenecks and eliminate waste in order to use resources more efficiently. These approaches are based on the Lean principles from the Toyota Production System. With value stream orientation, you shorten your throughput times, increase your organization's ability to deliver and sustainably improve quality and customer satisfaction, which leads to better and sustainable profitability for your company.

With value stream orientation, you shorten your throughput times, increase your organization's ability to deliver and sustainably improve quality and customer satisfaction, which leads to better and sustainable profitability for your company.

What are value streams?

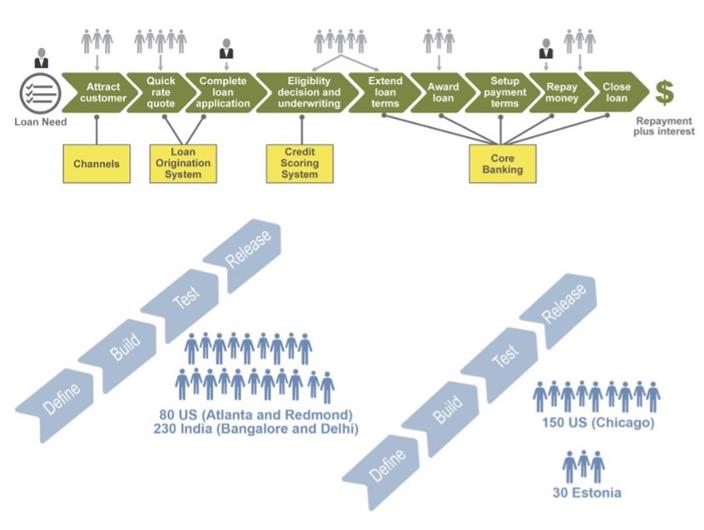

Value streams describe how value flows in a company and ultimately reaches the customer. A value stream is the sequence of steps required to deliver a product or service. A distinction is made between two types of value streams;

Operational value streams ;include all the steps necessary to deliver products or services to the end customer. They are at the heart of daily business operations, realizing value such as production, service delivery, support and logistics. Examples include the fulfillment of orders or the provision of services. Operational value streams ensure that the customer is continuously supplied with the product or service.

Development value streams focus on developing the solutions and systems that support operational value streams. These include activities such as the planning, development, validation and introduction of new products or systems. The goal is to provide the technological and organizational capabilities that operational value streams need to function effectively. Development value streams are therefore more innovation-driven and contribute to the continuous improvement and adaptation of the solutions used in operational value streams

What does value stream orientation mean?

Value stream orientation aims to avoid waste. This is achieved by consistently aligning all of a company's activities and processes to create maximum benefit for the customer. All steps required to provide a product or service are viewed as a coherent value stream - from the initial customer inquiry to the delivery of the end product or provision of the service.

7 steps to greater efficiency with value stream mapping

First of all, you gain a clear overview of your current processes. Together, we identify weaknesses and bottlenecks that slow down your processes and waste resources.

1. identification of the value stream

Determine which product or service process is to be analyzed. This includes defining the start and end point of the value stream.

2. mapping of the current value streams (actual status)

All activities that contribute to value creation are visualized. This includes process steps, waiting times, material and information flows as well as participants.

3. measurement of throughput times and bottlenecks

Time, resources and possible delays are analyzed to identify inefficiencies such as waiting times or overproduction.

4. analysis of bottlenecks

Problematic areas (e.g. long waiting times, bottlenecks) are highlighted in order to identify potential areas for improvement.

5. creation of the target state (target state)

An optimized value stream is designed to minimize waste and maximize efficiency. This also includes the reduction of unnecessary steps and waiting times.

6. implementation of the improvements

The measures required to convert from the actual to the target status are planned and implemented.

7. continuous improvement

After implementation, the processes are regularly reviewed to ensure further improvements

Contact us or make an appointment. We are Timo Foegen, Yvonne Fischer, Tina Eisoldt, Daniel Votta and Lutz Koch. We look forward to working together to make your company even more efficient.

Value stream orientation as a design principle for organizations

We often encounter companies in which value creation runs through different functional departments, resulting in delays in delivery due to handovers, dependencies or competing priorities. We therefore help you to continuously and in small steps align the process and organizational structure with the identified value streams in the sense of holistic value stream analysis;

Deliverable organizations

The ability to deliver and customer focus are crucial characteristics for the success of any company. When teams and departments work together reliably and effectively, products and services are delivered on time. Read here which building blocks are relevant for this.

Leading deliverable organizations through change

Organizations in today's world need leaders who create the framework for delivery capability and customer orientation. In this training course, you will develop your leadership skills for a modern organization in a complex world.

Masterclass Deliverable Organization

Do you use agile approaches or agile scaling in your company and are now looking for a suitable organizational design as a structure and framework? Then this Masterclass Deliverable Organizational Design is just right for you!

When working harder is not the solution ...

In the modern business world, where speed and efficiency are critical, leaders are often looking for ways to push their teams to higher [...]

What is an agile mindset?

An agile mindset is the cultural basis for an agile organization. On the way from a traditional to an agile organization, not only agile methods are important, but also a cultural change towards a more agile mindset.

SAFe Value Stream Workshop

Identify Value Streams and Agile Release Trains in the Value Stream Workshop: this is a key event for a successful SAFe implementation. Maximize value creation through an efficient design of your Value Streams and ARTs.

Scaled Agile Framework (SAFe)

SAFe is the most widely used framework for scaling Scrum and agility. It offers agile solutions for all levels of an organization: from teams and departments to corporate management.

How many value streams are there and why?

Your contact::

Malte Foegen